AN ISO 9001 : 2008 CERTIFIED CO

AN ISO 9001 : 2008 CERTIFIED CO

3D printer has gone through many years of study and development and still every month there are many new printers are coming in the market with new specification. Basically there are serval types of technologies for 3D printer, all this printer have been used for different application so you need to select which type of technology can do your work accurately and in less time after finding that you have to decide which company is providing maximum specification with minimal price although support and service also does matter after purchasing printer. So here we will understand different types of technologies in 3D printer and limits of all these technologies.

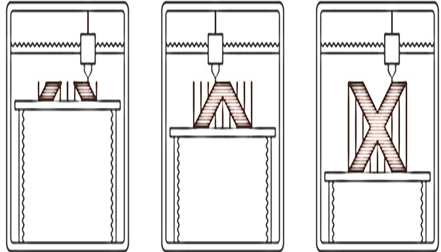

1) Fused Filament Fabrication (FDM)

FDM is 3D printing process which uses thermoplastic material to make layers. Filament head is moved under computer control to define the shape of model. FDM printer supports various thermoplastic material so you have vast variety on selecting material of your model. Generally, you can see the layer line in printed model due to height of layer so polishing is required after printing.

Application: prototype, model

Print quality: 200um to 250um

Speed: 70mm per hour

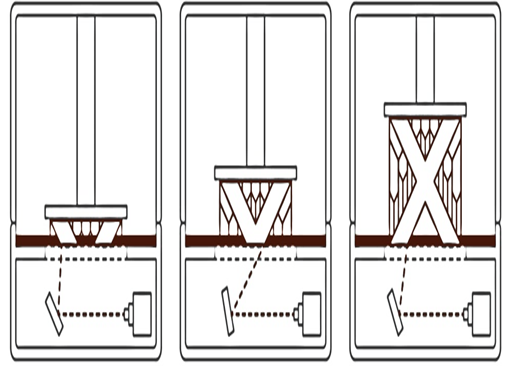

2)Vat Polymerization

Vat Polymerization is method in 3D printing which uses light to cure photosensitive liquid. In vat polymerization there is mainly two method SLA and DLP. SLP printer uses laser to cure layers and DLP printer project full image in photosensitive liquid so, speed of DLP printer is 3 to 5 times more than SLA printer. These types of printersare used in jewelry casting, accurate prototyping, dentistry and medical due to its seamless print quality and fast speed.

Application: casting, dentistry, medical, prototype, model

Print quality: 10um to 150um

Speed: 25mm per hour (50um layer)

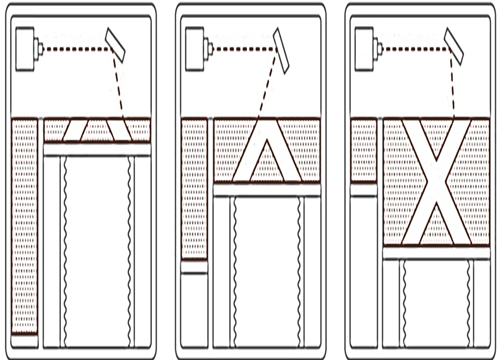

3)Power Bed Fusion

Powder bed fusion uses laser beam, heat or electric beam to melt and fuse material together to form a three-dimensional object. Based on melting method there are four types Selective heat sintering (SHS), Selective laser sintering (SLS), Electron beam melting (EBM), Multi jet fusion (MJH). This method is slowest method in 3D printing due to many processes in printing. Range of material is wide including ceramic, glass, plastic and alloys can be used to make 3D objects. Usually, these types of printer are costly and heavy because of its complex machinery.

Application: Aerospace, automotive, machinery parts

Print quality: 50um to 150um

Speed: 5mm per hour

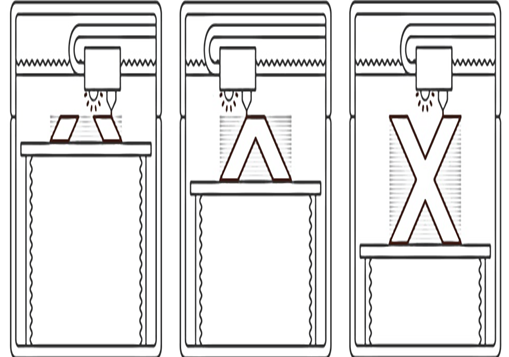

4)Material/Binder Jetting

Material jetting process uses printhead to dispense droplets of photosensitive material that solidifies under UV light. Material jetting creates parts of high dimensional accuracy with a very smooth surface finish. Advantage of material jetting is the capability to produce accurate multi material and multi-color parts.

Application: tooling and injection molding

Print quality: 16um to 50um

Speed: 10mm per hour

You need to recognize which technology in 3D printing is best for your application and find the best company for your printer.

In next article we will see which are the parameters that describe accuracy and quality of 3D printer.