AN ISO 9001 : 2008 CERTIFIED CO

AN ISO 9001 : 2008 CERTIFIED CO

Induction Melting Furnaces

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. An Induction Power Unit Flow into A Furnace And Through A Coil Made Of Hollow Copper Coil. This Creates An Electromagnetic Field That Passes Through Conductive Metal Charge Inside The Furnace. This Induces Electric Current To Flow Inside The Metal Charge Itself, Producing Heat That Rapidly Causes The Metal To Melt. Although Some Furnace Surfaces May Become Hot Enough To Present A Burn Hazard, With Induction, You Heat The Charge Directly, Not The Furnace. Induction Melting Offers.

Induction Heating Is Considered A Green Technology, As It Does Not Put Off Any Harmful Emissions Into The Atmosphere, Since Heat Is Being Generated By The Alternating Magnetic Current Into Graphite Crucible. Other Advantages Of Casting Gold Are Very Fast Heat-Up Times, Frequency Stirring For More Homogenous Melts And Induction Melting Technology Does Not Heat Up The Atmosphere The User Is Working In. The Only Heat Being Generated Is The Heat From The Actual Melt.

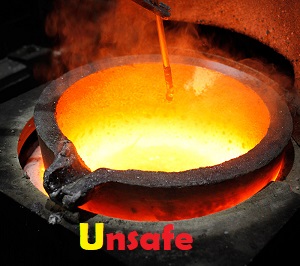

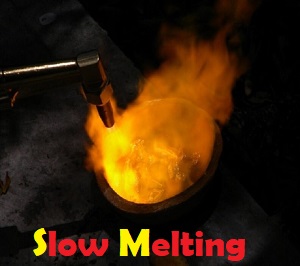

Traditional Gold Melting

The Traditional Gold Melting Method Was Adopted In The Earliest Periods Of The Gold-Rush Years, And It Is Very Much The Same Method Utilized In Several Parts Of The World, Most Especially Where There Is Limited Access To The Latest Gold Melting Machines Or Technology. The Gold Is Melted In An Open, “Holding” Crucible With Heat From A Gas Furnace That Can Increase The Temperature Of The Environment Where The Heating Is Taken Place. The Major Headaches With The Traditional Gold Melting Method. That It Requires Plenty Of Workers; It Is Environmentally Unfriendly; Some Gold Material May Be Lost During The Procedures; And, There Is No Way To Prevent Oxidation, And Other Corruption That May Affect The Gold Quality.

|

Traditional Melting Methods |

Induction Melting Method |

|

As There Is Resistance Coil, Chances Of Defusing Of Coil Are Frequent. Due To This Oxidization The Coil Corrodes. |

Coil Is Of Heavy Gauge Hollow Copper Pipe Having High Temperature And Double Insulation. Due To Circulation Of Cold Water, The Coil Lasts For A Very Long Time. |

|

First Melting Usually Takes As Long As 30 To 45 Minutes, Hence The Chance Of Oxidization Is More And Also There Are Chances Of Metal Loss. |

First Melting Takes Only 10 To 15 Minutes, Resulting In Null Oxidization And Zero Loss Metal. |

|

In This Method, The Coil Gets Heated First & Then The Heating Of Crucible Takes Place Followed By The Metal Heating, Which Results In Loss Of Heat And Metal. |

In This Method The Metal Heats With The Help Off Frequency And So There Is No Loss Of Heat And Metal. |

|

Due To The Heat Loss The Power Consumption Is Always More. |

Due To No Loss Of Heat The Power Consumption Reduces Significantly. |

|

Because Of No Stirring Effect The Metal Does Not Properly Melt. At The Time Of Pouring Of The Ready Metal It Is Found That He Metal Oxides Also Come Out With The Finished Metal Creating As Improper Metal Stock Or Rod. |

Because Of No Stirring Effect The Metal Oxides Rise To The Top Of The Melting Unit Creating A Separate Layer Without Blocking The Flow Of Pour Metal For Making The Metal Stick Or Rod. |

|

As There Is No Water Circulation The Temperature Of The Workshop Unit Remains Hot For Very Long Time. |

Due Ti Chiller, The Machine Gets Cooled Within 2-3 Minutes And The Temperature Of The Workshop Unit Remains Normal. |

|

There Is No Auto Stirring And The Metal Is Stirred With The Help Of A Carbon Rod. The Metal Sticks To The Carbon Rod Leading To Loss Of Metal And Also Mixture Of Carbon With Metal. |

In This Method There Is Auto Stirring Without The Need Of A Carbon Rod Resulting In No Loss Of Metal Which Remains Pure During The Entire Process. |

|

As There Is No Stirring Effect, There Is Additional Of Copper And Silver In Gold (99.99%) It Is Not In Uniform Micro Structure. |

Due To Automatic Stirring Effect There Is Perfect Distribution Of Copper And Silver In Gold (99.99%). |

|

Due To Second Melting Process The Heat Is Excessively Spread Out So It Is Very Difficult To Put Metal In The Form Od Dust Or Scrap In The Crucible. |

Here There Is No Heat Spread; Hence It Is Very Easy To Add The Metal Dust. Therefore There Is No Metal Loss. |