Induction brazing is the process of joining two or more metals using induction heating. Induction heating utilizes the electromagnetic field to provide heat without contact or flame. Induction brazing is more localized, repeatable, and easier to automate compared to traditional torch brazing. Induction brazing has been around for a long time but is only now coming into wider use due to advancements in induction heating power supplies.

Induction brazing can be used to join a wide variety of metals, including nickel, copper, cobalt, titanium, and steel. Some non-metals, such as ceramics, graphite, and glass can also be brazed using induction. It is a great way to join dissimilar metals and alloys, thanks to its localized heat and ability to join metals without melting them. Because induction brazing uses an electromagnetic field rather than flame, it can be used in many places where flame brazing is not possible or not safe.

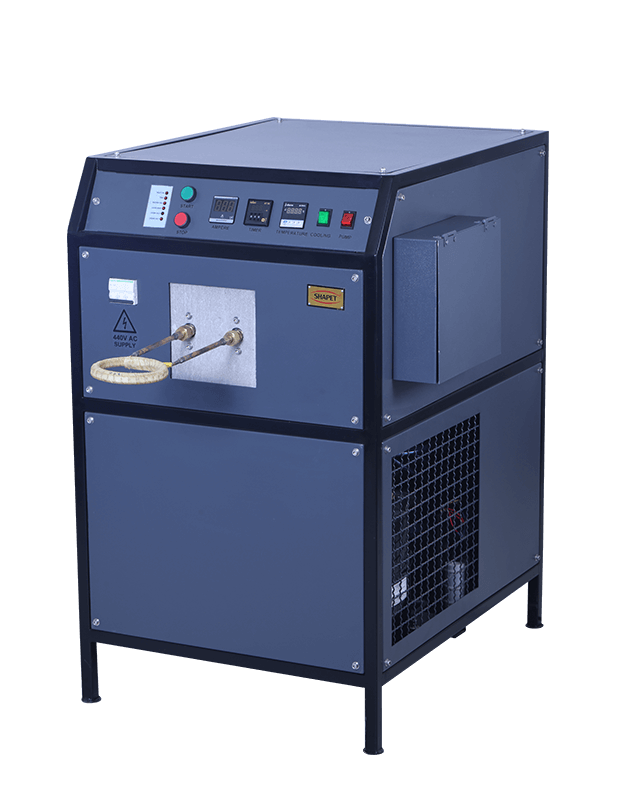

| Specifications |

| Power Supplier |

Three phase |

| Voltage |

440 volt AC |

| Absorbed Power |

5 kW to 10 kW |

| Cooling Water Temperature |

35° C |

| † Brimful Capacity †† Under Standard Condition |